An Ideal Partnership

In its most basic form, contract manufacturing is when one business agrees to assist in the production of goods for another business. In other words, a company hires a contract manufacturer to handle their production needs, whether it be to produce a single part or component, build complex assemblies, or oversee the entire process from initial build to fulfillment and logistics.

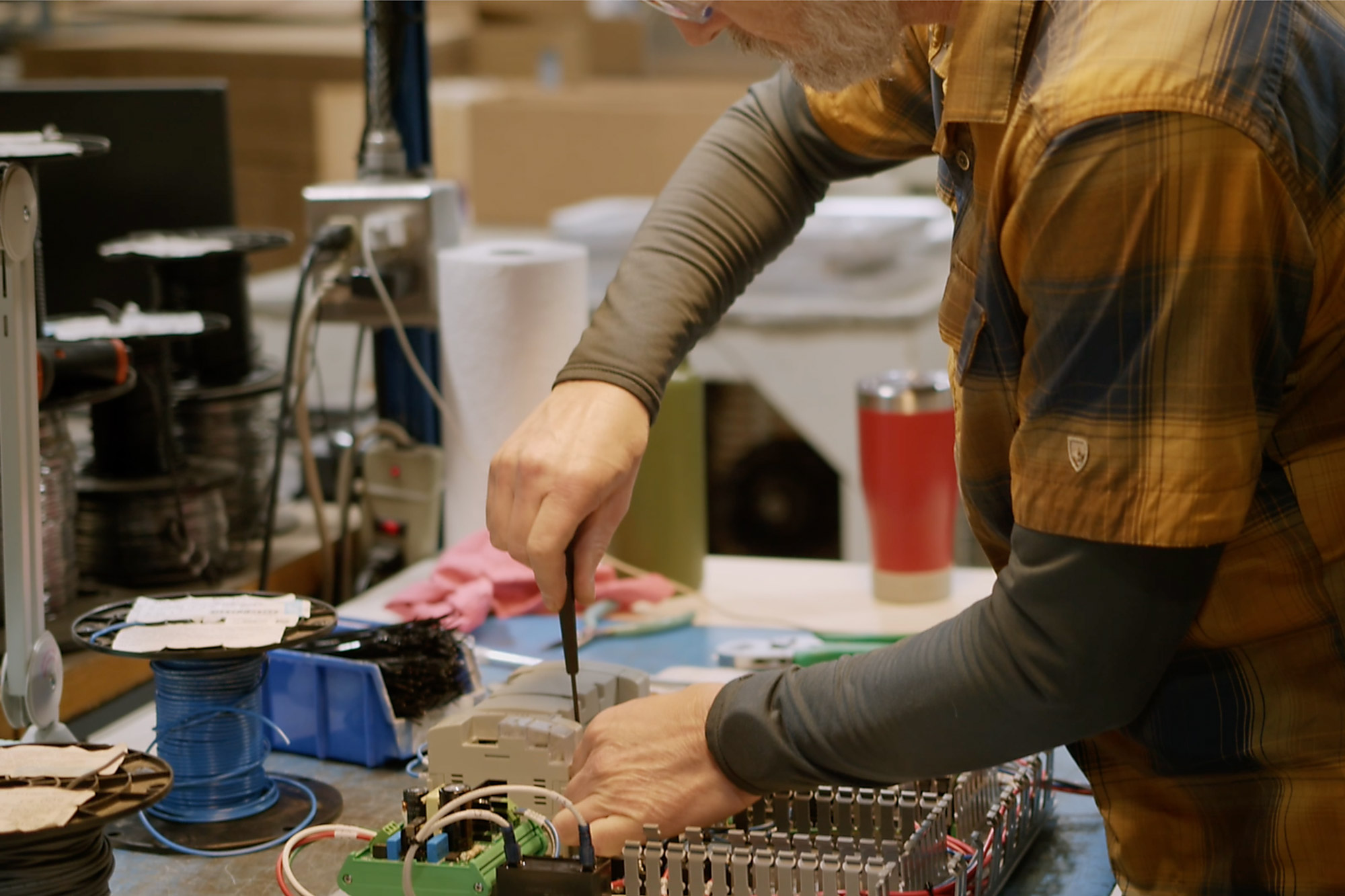

For many companies big and small, it is not practical or cost-efficient to purchase or build a large facility to house multiple pieces of expensive manufacturing equipment, keep full-time staff on to make and assemble their products, and oversee quality control and complex regulations compliance. That’s where contract manufacturers like Kalow Technologies come in. Contract manufacturers invest in facilities, specialty machinery, skilled labor, technology, insurance, and more, and make those resources available to multiple clients with varying needs. We act as your manufacturing arm – an extension of your company – and offer everything you need to get your products to market, from design for build, to production and assembly, to finish, logistics and distribution. We oversee all aspects of production, so you can focus on what you’re really good at: marketing, selling, customer service, and new product development.

For many companies big and small, it is not practical or cost-efficient to purchase or build a large facility to house multiple pieces of expensive manufacturing equipment, keep full-time staff on to make and assemble their products, and oversee quality control and complex regulations compliance. That’s where contract manufacturers like Kalow Technologies come in. Contract manufacturers invest in facilities, specialty machinery, skilled labor, technology, insurance, and more, and make those resources available to multiple clients with varying needs. We act as your manufacturing arm – an extension of your company – and offer everything you need to get your products to market, from design for build, to production and assembly, to finish, logistics and distribution. We oversee all aspects of production, so you can focus on what you’re really good at: marketing, selling, customer service, and new product development.

Companies with limited capital and/or human resources, smaller or fluctuating production runs, or limited space benefit greatly from having a contract manufacturer as a partner. It’s a very important relationship, and one that can set you up for long term success if the fit is right. Think of it as hiring a whole team of employees with varying levels of expertise and special skills. As you go through the process of selecting a contract manufacturing company, you’ll want to look for certain elements that can tell you a lot about the way they do business.

The most important factor to consider is whether or not the company has an ISO certification. This third-party evaluation helps ensure that the manufacturing  company follows all the appropriate statutory and regulatory requirements, so you can rest easy knowing that your manufacturing partner is meeting these standards. ISO 9000 is defined as a set of international standards on quality management and quality assurance developed to help companies effectively document the quality system elements needed to maintain an efficient quality system.

company follows all the appropriate statutory and regulatory requirements, so you can rest easy knowing that your manufacturing partner is meeting these standards. ISO 9000 is defined as a set of international standards on quality management and quality assurance developed to help companies effectively document the quality system elements needed to maintain an efficient quality system.

-

- Is the facility clean and well-managed?

- Is their equipment state of the art and well-maintained?

- Do they follow best practice safety standards?

- Are their employees skilled, engaged, competent and responsive?

- What do they offer for supply-chain management and logistics support?

- Can they meet your demands now and expand as you grow?

Not all contract manufacturers are created equal, so make sure you ask a lot of questions and voice any concerns up front, state clearly your expectations and understand theirs. The right partner can be the key to getting your products to market with superior quality and peace of mind.

Related Posts

Kalow Engineering Expands (Rutland, VT) This fall, Kalow Technologies moved our growing team of engineers from their section

(Rutland, VT) – Kalow Technologies, a leading contract manufacturer of packaging, beverage dispensing, ag tech, and 3D printing equipment

We're pretty excited about this addition! Kalow Technologies took receipt of its new Trumpf TruBend 7050 brake press