Kalow Engineering Expands

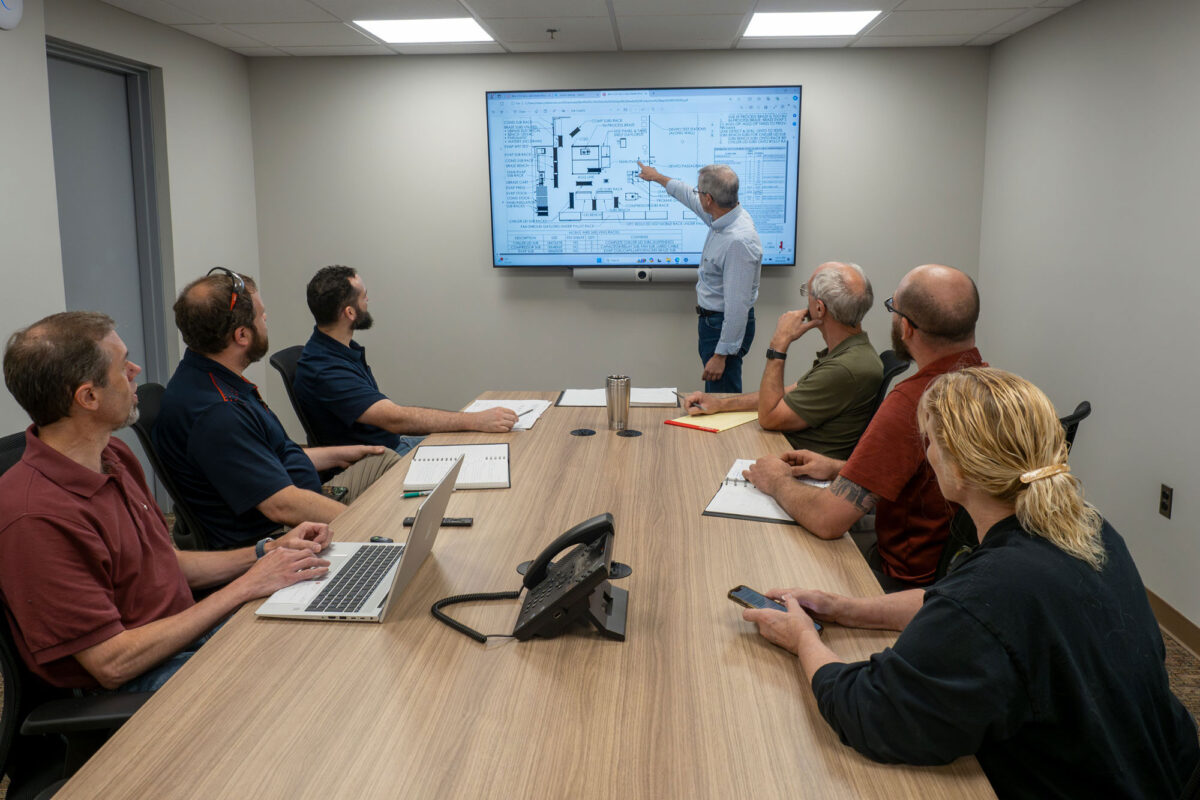

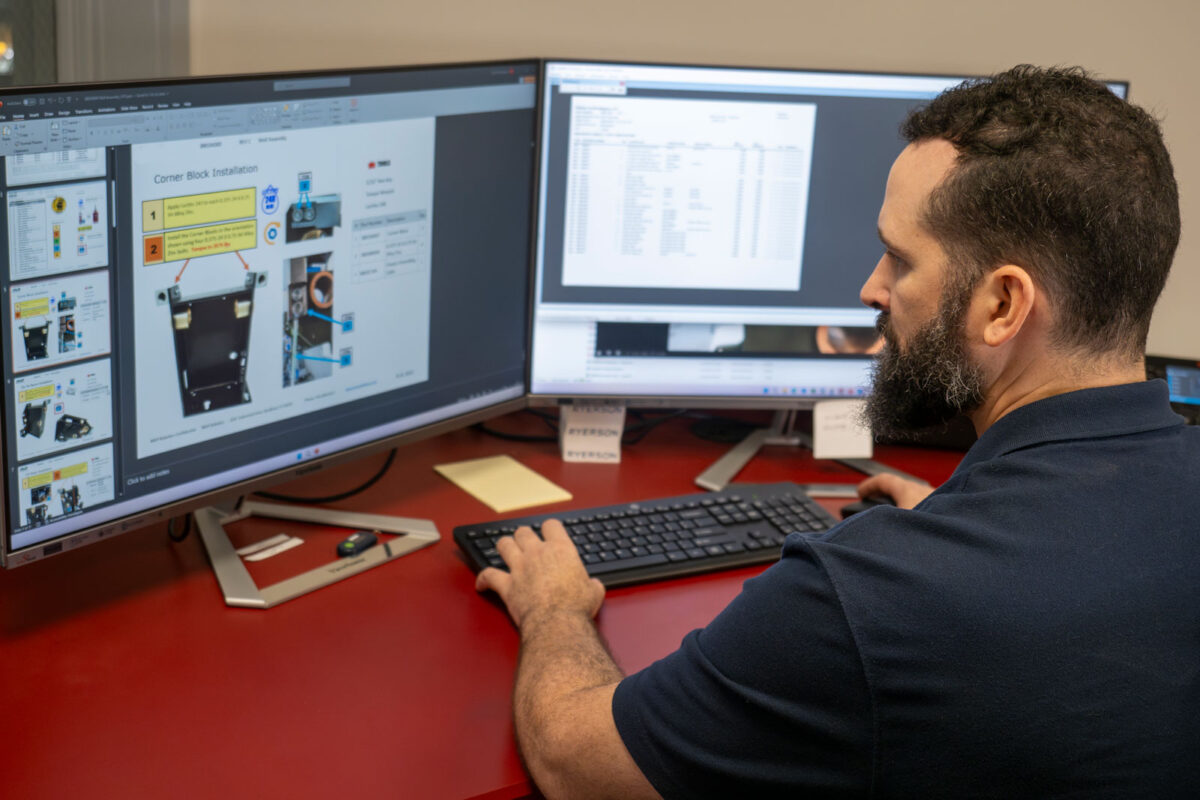

(Rutland, VT) This fall, Kalow Technologies moved our growing team of engineers from their section in the bustling administration offices into a their newly-finished facilities. The new engineering department is on the second floor above the recently expanded, large-scale production facility which Kalow opened in late in 2023. In addition to the roomy new work spaces, the move gives the engineering team an open research lab, a 3D printer, new inspection equipment, dedicated conference room, and a lot more space to design, problem solve, and meet with clients in a quieter area; while still being just a few steps from the production floor.

Our engineers spend much of their time working directly with the production teams out on the floor to ensure that both the products and their production systems are as efficient and ergonomic as possible. If we need to refine a part, or build something new to help the line function better, we can design it and walk it right to the fab shop to manufacture and then test it in real time in our new facilities. This seamless integration between engineering and production saves everyone time and money, and our new, open flow facility makes that process even more efficient.

“We’re excited for our customers to visit and interact in the new engineering space and see all that’s been happening at Kalow Technologies,” said Kalow president, Jon Blatchford.

“We’ve seen a great deal of growth and development, and that growth has come quickly, with both new customers and employees. The new engineering facility, ongoing expansion and investment in cutting edge technology has increased our production capacity on all levels, ” said Nick Flanders, Sr. Customer Relations Manager.

Kalow’s recent growth has come from both new and existing clients and represents a significant diversification of their product lines and equipment needs.

Related Posts

With the addition of their new automated Trumpf TruBend 7036 press brake, Kalow has increased their output significantly.

Kalow Gives Back (Rutland, VT) – In September, the team at Kalow conducted a successful fundraiser for the

An Ideal Partnership In its most basic form, contract manufacturing is when one business agrees to assist in